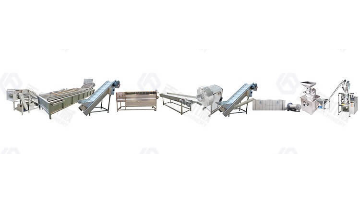

Introduction of the garlic powder production line

The garlic powder processing line has continuous automatic production, fast processing speed, high output, and good quality. It includes garlic clove separator, garlic peeling machine, garlic washing machine, garlic slicer, air dryer, garlic dryer, garlic grinder, garlic powder packaging machine, and other equipment, which can be used for deep processing of garlic dehydration slices, garlic powder, etc. . The production line adopts advanced technology, high garlic output, and direct sales at factory prices. This is the best choice for the garlic powder business and the most ideal equipment for garlic processing at present.

Components of garlic powder processing line

A complete large-scale garlic powder processing plant mainly includes: splitting machine, peeling machine, washing machine, slicing machine, dehydrating machine, dryer, powder grinding equipment, packaging machine, etc., each equipment interacts with each other. Connected by a hoist.

Garlic clove separator: It is mainly used to separate garlic cloves and garlic stalks and partially peel the garlic cloves. Garlic bulbs can be used in any size, with the advantages of no damage to garlic cloves and high peeling rate. The equipment is easy to operate, has high production efficiency, easy cleaning, and low failure rate.

Garlic peeling machine: adopts electric and pneumatic automatic control to make garlic automatically feed, peel, and separate the garlic from the peel. There is no damage to garlic, and the peeling rate is high.

Garlic washing and rinsing machine: Wash off impurities before slicing, rinse off the garlic film, remove glue and debris to prevent yellowish-brown during drying. The whole is made of stainless steel. Through the effect of water circulation, the garlic cloves will be removed during the initial cleaning of the garlic. After the rinsing, the garlic cloves will follow the conveying system and enter the next process.

Garlic slicing machine: Cut the garlic cloves into even slices. The thickness of the slices should be 1.5-2mm. The garlic slices processed by this high-efficiency garlic slicer have standard product specifications with uniform thickness and uniform size, which has a good effect on the later drying process. This uniform garlic slice can keep the time and effect of the drying process under the same conditions, so the overall drying effect will also be very high, which meets the processing standards of large-scale enterprises in the drying of garlic slices.

Air dryer (Dehydrator): Garlic slices can effectively remove water and shorten the drying time before drying after washing. The main purpose is to pre-dehydrate the garlic slices before drying. Because the garlic slicer uses the principle of water washing and slicing, the moisture content of the garlic slices after cutting is super high, plus the water contained in the garlic slices. If you don’t go through the preliminary dehydration treatment and directly send it to the drying host, it will cause serious cooking conditions, which will have a huge impact on the quality of the dried garlic slices. Therefore, the garlic slice dehydration processing equipment is used for preliminary analysis. Dehydration processing is very necessary.

Multi-layer belt garlic slice dryer: The dryer is the key equipment, which determines the effect and quality of garlic slices after processing. Using our mesh belt type garlic slice dryer, with an intelligent control system, can make garlic slices The drying is always maintained in a reasonable drying environment to ensure the effect of the finished product. The use of this garlic slice dryer has the advantages of large processing output, high degree of automation, controllable drying effect and quality, and adjustable drying time. Flexible heat source selection: Coal, wood chips, natural gas, diesel, propane, electricity, etc.

Garlic powder making machine: Grind dried garlic slices to a fineness of 10-120 mesh. The garlic grinder is air-cooled or water-cooled and can work continuously for a long time.

Garlic powder packaging machine: Generally speaking, the garlic powder business requires automatic garlic powder packaging equipment. The garlic powder packaging machine has a PLC control system, which is intelligent and controllable and can be quickly adjusted according to customer packaging requirements. Packaging weight and quantity are automatically adjusted.

Advantages of garlic powder processing line

| 50-100kg/h small output garlic powder processing line | ||||

| Number | Name | Power | Size | Output |

| 1 | Garlic Clove Separator | 0.74KW | 690*710*1050mm | 200kg/h |

| 2 | Garlic Peeling Machine | 0.2KW | 640x660x1370mm | 150kg/h |

| 3 | Garlic Slicer | 0.75KW | 720*540*880mm | 300kg/h |

| 4 | Dryer | 3KW | 2100*930*2100mm | 50-100kg/h |

| 5 | Grinder | 5.5KW | 750*600*1260mm | 30-150kg/h |

| 6 | Packing Machine | 1.6KW | 700*750*1650mm | 30-60 packs/min |

| The garlic powder processing line can be equipped according to the user’s requirement and the production demands. | ||||